This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

CUSTOMER

Lucky & Company

PROJECT CATEGORY

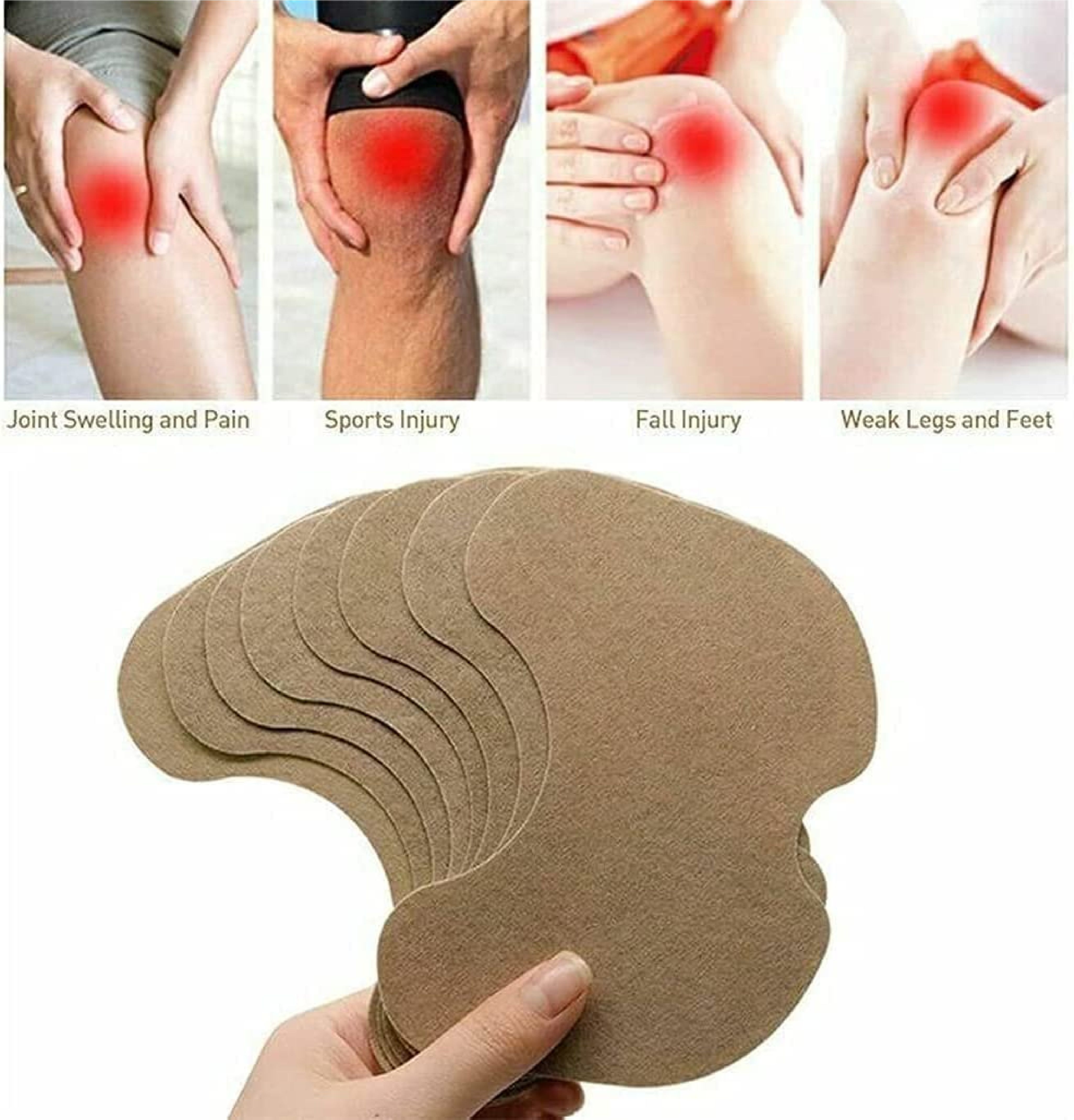

Transdermal Patches continue to grow in popularity as manufacturers find new ways to delivering Vitamins, Herbs and Supplements through the skin. As there are fewer side-effects and allows for easy removal of the patch in the case that there is an adverse reaction.

COMPLETED

2020-06-30T00:00:00

PROJECT BUDGET

₹ 3000000

PROJECT DESCRIPTION

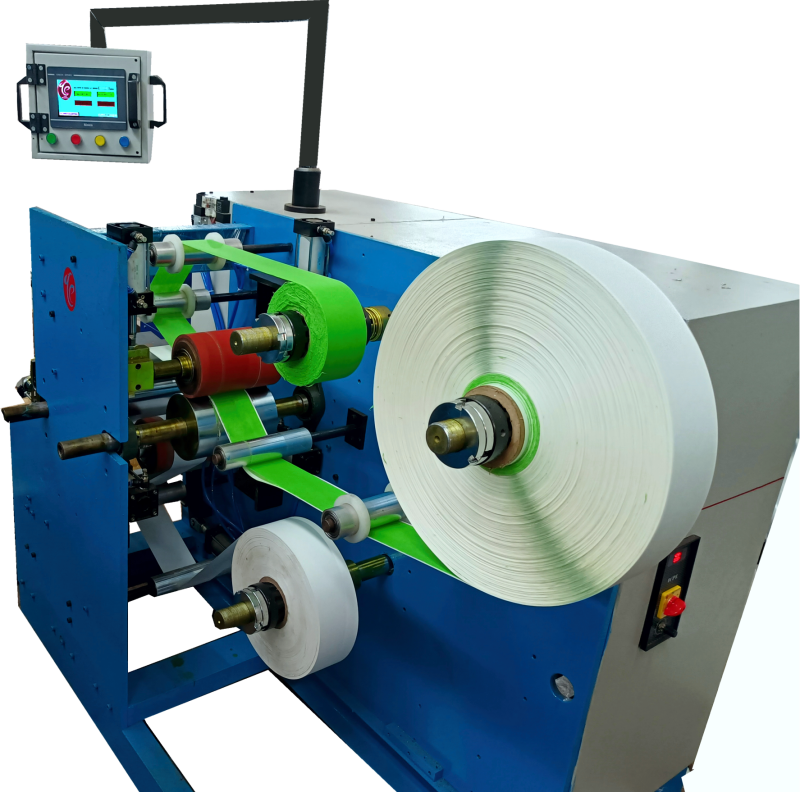

Using Hot Melt Adhesive technology with medicine is a better solution for Transdermal Patches. The medicines are to be dissolved in oil then this mixture of oil is added to the Hot Melt Adhesive. Mixed thoroughly and made homogeneous. This medicated adhesive is used with Hot Melt Coating Machine to coat the required grammage on the release liner. Then it is laminated to the backup material. The laminate is then punched or cut to the desired size and shape.

CUSTOMER REQUIREMENT

Transdermal Patch Making: 1. Mixer: The mixer is used to mix the medicines and adhesive at maintained temperature and make a homogeneous coating material. 2. Slitting: The Jumbo reels of Release liners and back up materials are slitted in the desired width. 3. Coating: A hot melt coating machine to coat the medicated adhesive on the back up material. 4. Punching and Cutting: A machine to punch shapes or holes in to the plaster and cut it to he size. 5. Packing and Sealing: The pouches or boxes filling and sealing facility. This is either Manual, seme automatic or Automatic.

WHAT WE DID

Trasy Enterprises supplied the machines

RESULT

Succeful Production of the pain relief patches

CUSTOMER

Lucky & Company

PROJECT CATEGORY

Transdermal Patches continue to grow in popularity as manufacturers find new ways to delivering Vitamins, Herbs and Supplements through the skin. As there are fewer side-effects and allows for easy removal of the patch in the case that there is an adverse reaction.

COMPLETED

2020-06-30T00:00:00

PROJECT BUDGET

₹ 3000000

PROJECT DESCRIPTION

Using Hot Melt Adhesive technology with medicine is a better solution for Transdermal Patches. The medicines are to be dissolved in oil then this mixture of oil is added to the Hot Melt Adhesive. Mixed thoroughly and made homogeneous. This medicated adhesive is used with Hot Melt Coating Machine to coat the required grammage on the release liner. Then it is laminated to the backup material. The laminate is then punched or cut to the desired size and shape.

CUSTOMER REQUIREMENT

Transdermal Patch Making: 1. Mixer: The mixer is used to mix the medicines and adhesive at maintained temperature and make a homogeneous coating material. 2. Slitting: The Jumbo reels of Release liners and back up materials are slitted in the desired width. 3. Coating: A hot melt coating machine to coat the medicated adhesive on the back up material. 4. Punching and Cutting: A machine to punch shapes or holes in to the plaster and cut it to he size. 5. Packing and Sealing: The pouches or boxes filling and sealing facility. This is either Manual, seme automatic or Automatic.

WHAT WE DID

Trasy Enterprises supplied the machines

RESULT

Succeful Production of the pain relief patches