Description

Product details

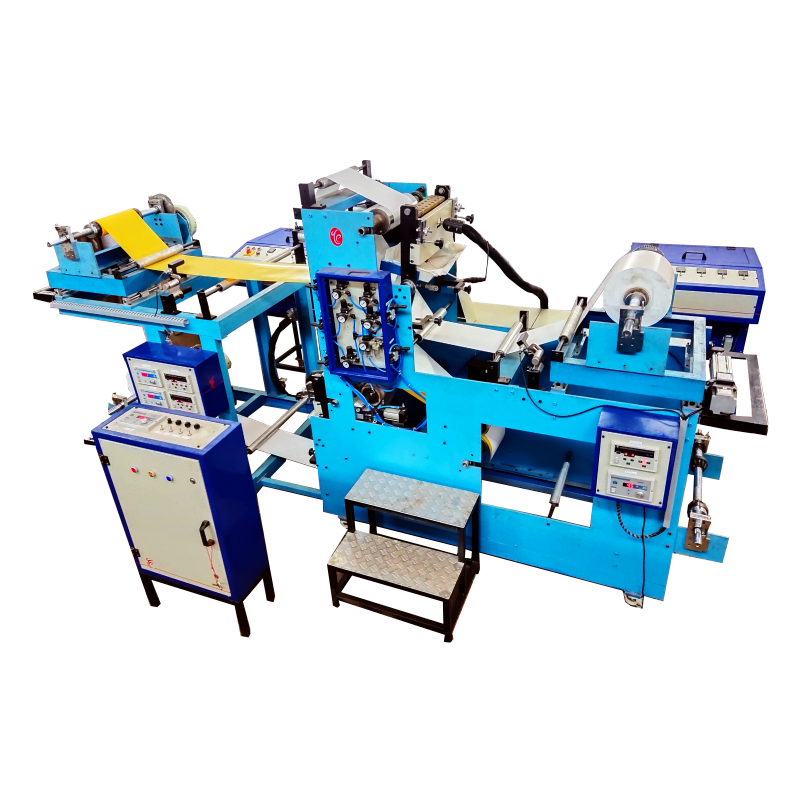

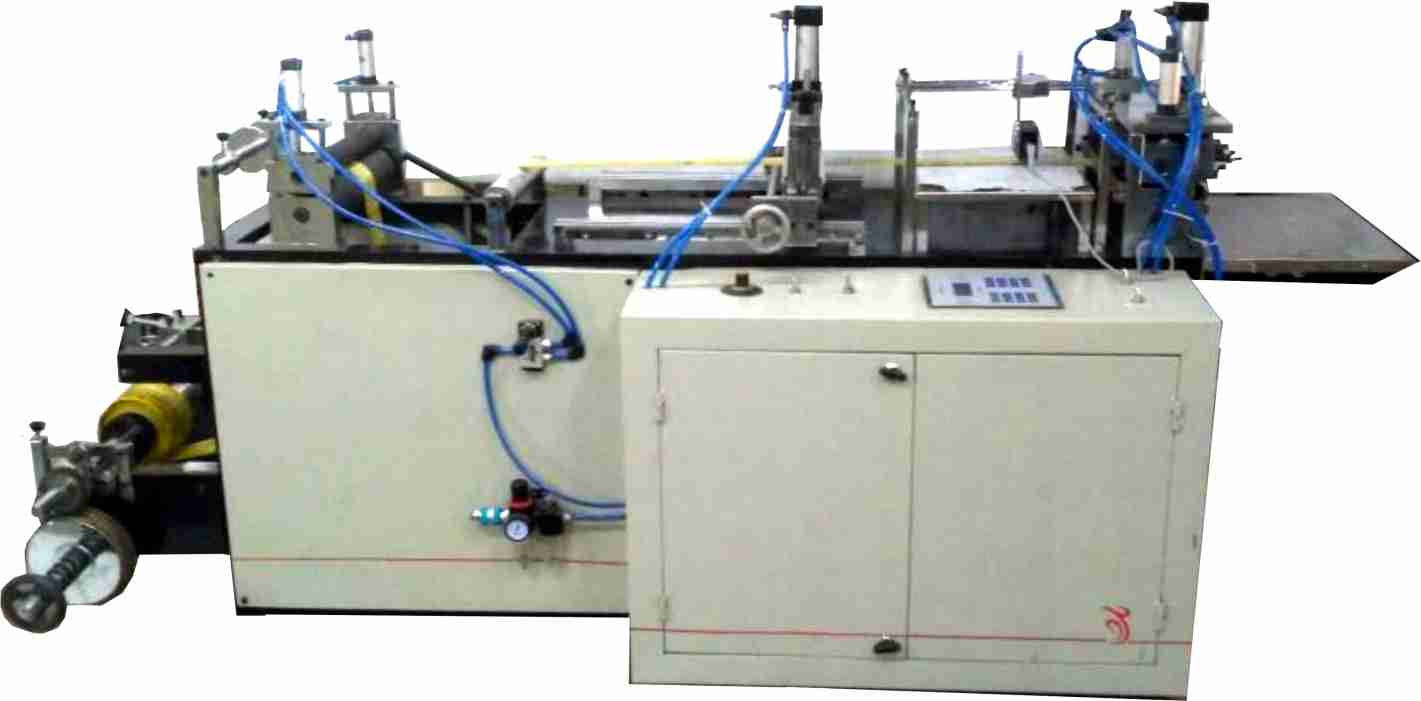

A 300mm width Hot Melt Coating Machine with both side coating at same time and Sheet cutting machine Hot Melt Coater Specification: This machine will make rolls of 325mm (Max.) width & max 600mm dia. with 30 gsm hot melt coating. Process Silicon paper of 300mm will be coated with HM 30 gsm. Lamination (transfer of HM on PVC) of Si paper & 0.270mm PVC film. Winding of Si paper & PP/PVC roll. Machine Type: Die coating Max. Size of coating: 300mm, GSM: 15 to 65 Max. Speed of coating : Speed 20 mpm @30gsm M/c specifications: Unwind 1: To hold 310 mm max. width material. (Si Paper)450 mm Dia. Max. 76 MM core ID. Powder Brake Web Guide Unwind 2: To hold 300 mm width material. (PVC of 0.27mm) 450 mm Dia. Max. 76 MM core ID. Powder Brake Web Guide Coating Station: Die coating.( 2 Sets) Accurate Temp. Control. All silicon rolls dynamic balanced. Back up roller Pneumatically operated Lamination Nip: Dynamic balanced Metal roll & Silicone roll Operation & pressure Pneumatic Drive to the nip Rewind : for PVC + Si Paper To hold 310mm max. width material. 600 mm Dia. Max. 76 MM core ID. Tapper tension controlled winding. AC Drive for controlled winding. Permelter: (2 Sets) Tank capacity 20 Lit. Melting Capacity 8 Lit/hr liquid tank capacity 5 Lit. Pump Capacity 0.4 Lit/Min Accurate Temp. Control. Accurate flow control Hot melt Hose (2 Sets) To Supply 0.4 Kgs/hr Length 2 m Accurate Temp. Control. DIMENTIONS: 3 m X 2 m X 2 m Total Electrical Load : Motors 5 HP, Heaters 7.5 KW watch video: https://youtu.be/aqrBvo2mE8w?si=70DMDgRqG2v3ldsE