Description

Product details

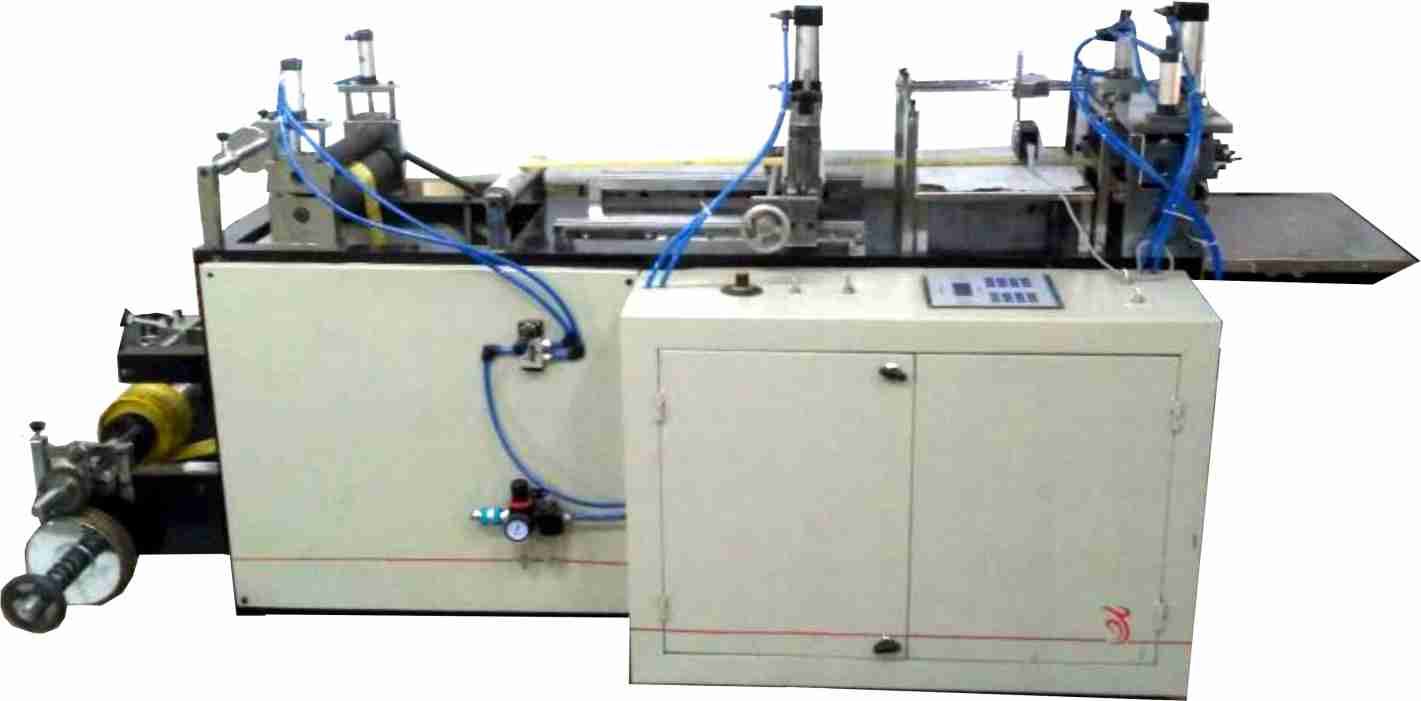

A 300mm width Hot Melt Coating Machine with both side coating and Printing at same time and Sheet cutting machine. Hot Melt Coater Specification: This machine will make rolls of 300 mm (Max.) width & max 600mm dia. with 30 gsm hot melt coating. Process Silicon paper of 300 mm will be coated with HM 30 gsm. Lamination (transfer of HM on PVC) of Si paper & 0.270mm PVC film. Winding of Si paper & PVC roll. Machine Type: Die coating Max. Size of coating: 300mm, GSM: 15 to 65 Max. Speed of coating : Speed 10 mpm @30gsm M/c specifications: Unwind 1: ( 2Sets) To hold 310 mm max. width material. (Si Paper)450 mm Dia. Max. 76 MM core ID. Powder Brake Web Guide Unwind 2: To hold 300 mm width material. (PVC of 0.27mm) 450 mm Dia. Max. 76 MM core ID. Powder Brake Web Guide Coating Station: Die coating.( 2 Sets) Accurate Temp. Control. All silicon rolls dynamic balanced. Back up roller Pneumatically operated Lamination Nip: Dynamic balanced Metal roll & Silicone roll Operation & pressure Pneumatic Drive to the nip Rewind : for PVC + Si Paper To hold 310mm max. width material. 600 mm Dia. Max. 76 MM core ID. Tapper tension controlled winding. AC Drive for controlled winding. Permelter: (2 Sets) Tank capacity 20 Lit. Melting Capacity 8 Lit/hr liquid tank capacity 5 Lit. Pump Capacity 0.4 Lit/Min Accurate Temp. Control. Accurate flow control Hot melt Hose (2 Sets) To Supply 0.4 Kgs/hr Length 2 m Accurate Temp. Control. 8. Printing Stations: Machined & Fabricated from MS Plate. Heavy construction made, vibration less to suit 10 m/min coating speed. Idlers of Aluminum seamless pipe by machining. Rubber rolls pneumatically operated and controlled. 9. DIMENTIONS: 3 m X 2 m X 2 m Total Electrical Load : Motors 5 HP, Heaters 7.5 KW WORKING DETAILS OF LABLE MAKING MACHINE: UNWIND : Max. 300mm film width with brake. CUTTING : Cutting is done by pneumatic knife with very simple procedure of blade setting. PUNCHING: Pneumatic punching unit with X/Y axis movement to position the 4 hole position. DRIVE : Main drive with PMDC drive with thirstier control for step less speed variation. PULLING DRIVE : AC servo motor driven by microprocessor based with pneumatic pinching rollers. CONTROL PANEL : Key board for setting length of sheet. All settings & counting numbers are displayed on LCD display. The basic program runs on microprocessor. COUNTERS: One integrator total production counter. Display of cuts per minute is also provided. Watch Video: https://youtu.be/We85mLoqtK4?si=FDZms25wslUTaoO7