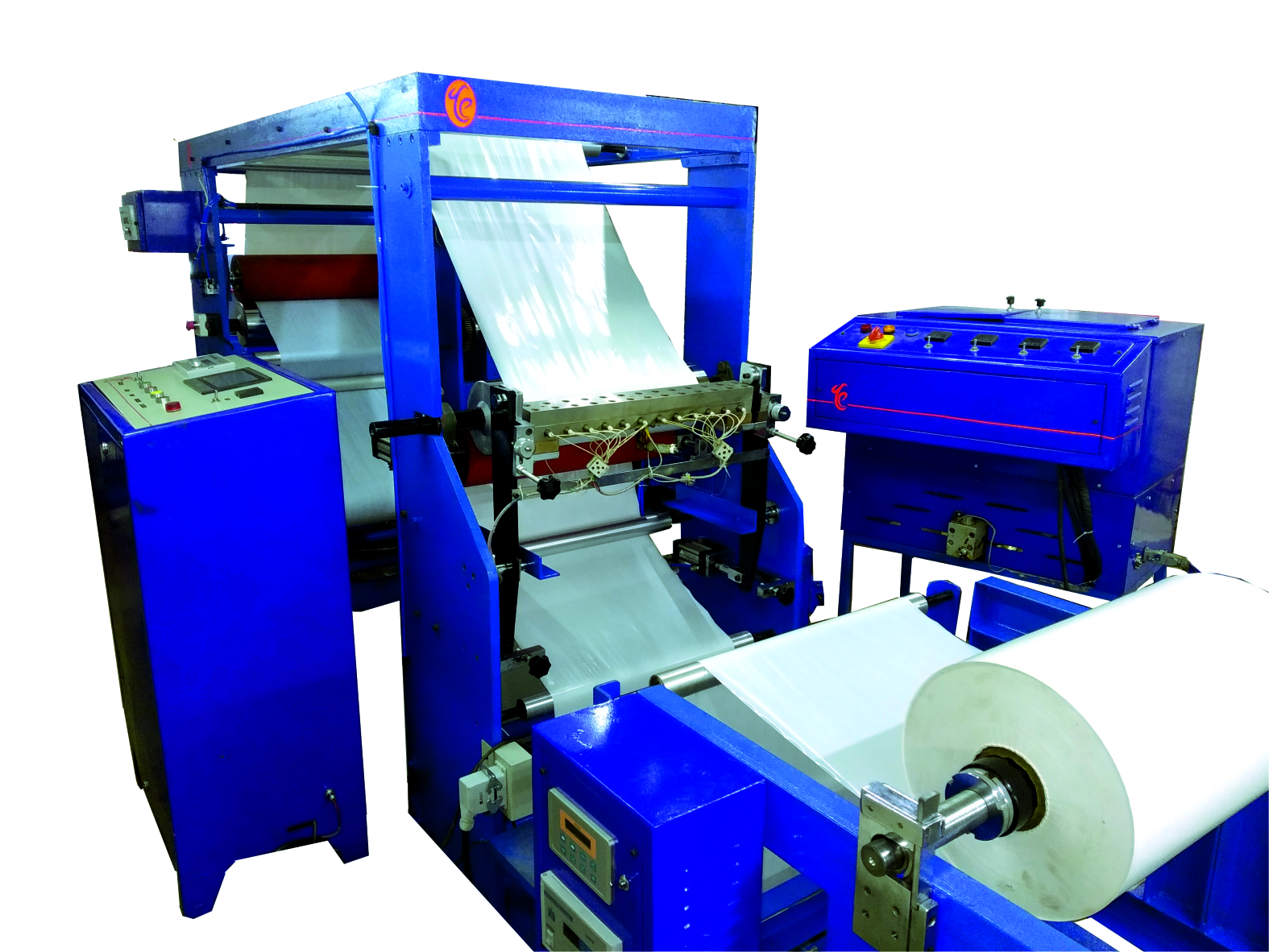

HOT MELT COATING MACHINE : ROLL TO ROLL The use of hot melt as a bonding adhesive in the industry has been transformed over the past few years and is gradually replacing conventional solvent or water-based systems and flame lamination. Trasy Enterprises is one of the leading designers and builder of a wide range of Hot Melt Coating machines. Accuracy & precision coating is assured. Our machines are high quality and are designed specifically for use in the packaging, speciality tapes, upholstery fabric lamination, medical packaging, surgical pouches, Insect sticky traps and other related industries. Hot Melt Coating process is very similar process to wax coating process. Hot melt adhesives are similar to wax. Hot melt adhesives are of two types: 1. The Thermoset hot melt adhesive. 2. The Pressure Sensitive Adhesive commonly known as PSA. This coating can be done with various methods. Commonly it was done with roller coating or gravure coating. Gravure coating gives uniform coating but the disadvantage of this coating type is every time you have to change the engraved roller for different grammage of coating. In roller coating the challenge was to achieve thin coating and high speeds. As the rotating roll churns the Hot melt and forms bubbles. This results in spotted coating. In both these processes the molten adhesive is exposed to the air and loses its heat so the hot melt adhesive changes its viscosity and this results in variation of coating thickness or in fuming due to high temperatures applied. Some time the hot melt degrades due to high temperatures and loses its sticking property. Hence, the best method to coat hot melt is through a SLOT DIE coating. Advantages of this process are minimum heat loss compared to the other processes. The molten adhesive is never open to air. (Safety factor) Can coat on almost all materials like BOPP, PET, Cloth, HDPE fabric, Felt, Paper, Nonwoven, Aluminium foil, etc. The HOT MELT COATING MACHINE made by TRASY ENTERPRISES has following features: Coating range Min. 15 gsm to Max. 600 gsm. Automatic setting of gsm from touch screen control panel. Even coating along the width and length. Calibrated glue melting capacity. Indicator for glue melt pressure to indicate the clogging of the filter. Hardened Die with special alloy steel to give more life. Automatic tension controls with magnetic powder brakes and clutches. Our Model ‘HMC 20’ ensures all these specialities:

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

HOT MELT COATING MACHINE : ROLL TO ROLL The use...

2019-10-19T06:34:28

HOT MELT COATING MACHINE : ROLL TO ROLL The use of hot melt as a bonding adhesive in the industry has been transformed over the past few years and is gradually replacing conventional solvent or water-based systems and flame lamination. Trasy Enterprises is one of the leading designers and builder of a wide range of Hot Melt Coating machines. Accuracy & precision coating is assured. Our machines are high quality and are designed specifically for use in the packaging, speciality tapes, upholstery fabric lamination, medical packaging, surgical pouches, Insect sticky traps and other related industries. Hot Melt Coating process is very similar process to wax coating process. Hot melt adhesives are similar to wax. Hot melt adhesives are of two types: 1. The Thermoset hot melt adhesive. 2. The Pressure Sensitive Adhesive commonly known as PSA. This coating can be done with various methods. Commonly it was done with roller coating or gravure coating. Gravure coating gives uniform coating but the disadvantage of this coating type is every time you have to change the engraved roller for different grammage of coating. In roller coating the challenge was to achieve thin coating and high speeds. As the rotating roll churns the Hot melt and forms bubbles. This results in spotted coating. In both these processes the molten adhesive is exposed to the air and loses its heat so the hot melt adhesive changes its viscosity and this results in variation of coating thickness or in fuming due to high temperatures applied. Some time the hot melt degrades due to high temperatures and loses its sticking property. Hence, the best method to coat hot melt is through a SLOT DIE coating. Advantages of this process are minimum heat loss compared to the other processes. The molten adhesive is never open to air. (Safety factor) Can coat on almost all materials like BOPP, PET, Cloth, HDPE fabric, Felt, Paper, Nonwoven, Aluminium foil, etc. The HOT MELT COATING MACHINE made by TRASY ENTERPRISES has following features: Coating range Min. 15 gsm to Max. 600 gsm. Automatic setting of gsm from touch screen control panel. Even coating along the width and length. Calibrated glue melting capacity. Indicator for glue melt pressure to indicate the clogging of the filter. Hardened Die with special alloy steel to give more life. Automatic tension controls with magnetic powder brakes and clutches. Our Model ‘HMC 20’ ensures all these specialities:

2019-10-19T06:34:28

Keywords

- high temperatures

- Thermoset hot melt

- Hot melt adhesives

- glue melt pressure

- wax coating process

- Melt Coating process

- hot melt degrades due

- magnetic powder brakes

- hot melt adhesive changes

- Hot Melt Coating machines

- Automatic tension controls

- touch screen control panel

- Pressure Sensitive Adhesive

- upholstery fabric lamination

Submit Your Enquiry